Content

We(bobe-paper machine) are professional in making paper machine,such as Napkin Machine,Slitting Machine,Handkerchief Machine, Cartoning Machine,Sealing Machine ect.

5.0 or 5.2 FX-SP-S Automatic Production Line Of Handkerchief Machine

Performance description

1.Bobe paper machine manufacturing 5.0 or 5.2 FX-SP-S Automatic Production Line Of Handkerchief Machine performance is good, efficient, stable, safe, high degree of automation, the separation of accurate, beautiful packaging, paper towel manufacturers ideal automatic paper towel production line, the majority of users unanimously respected.

Working principle

Slitting Machine in accordance with the specified size of the paper cut into paper, the machine in accordance with the specified specifications, patterns, embossing and automatic folding after the automatic counting and by folding, automatic packaging into a single package and bag in the handkerchief paper.

Machine characteristics

1.The use of vacuum adsorption assisted molding, embossed, cut off, automatically folded into small size, beautiful appearance, easy to carry the handkerchief paper.

2. Folded neat, smooth operation, the speed reached 800-1500 tablets / minute.

3.Can be adjusted according to the level of the tension of the base paper, paper embossed pattern, clear and chic pattern, paper neat and convenient packaging.

4.Can be customized according to user requirements production specifications of different models of handkerchief paper.

5.counting system: electronic counting jump, to ensure accurate number of sheets, easy to package, more efficient.

6.Automatic separation: through the PLC system has been folded a good amount of napkins in accordance with the specified number of automatic separation, effectively reduce labor costs and improve production efficiency.

7.Packaging line: through the packaging line has been folded a good napkin packaging into a single package or package, effectively reduce labor costs and improve production efficiency.

8.Embossing device: can be used to point flat, point to point steel roll, steel roller, wool roller, felt roller and other combinations.

9.Transmission control system: the use of advanced full servo drive control system, greatly reducing the failure rate, reduce the cost of machine maintenance and maintenance of the probability and maintenance time.

Recommend matching device

1.Gluing Composite Device: the paper is not separated, not easy to break, more beautiful three-dimensional pattern, feel more fluffy and more flexible, strong water, can be used for restaurant dining, toilet towels, kitchen oil, water.

2.Printing device: the monotonous pure color napkins given colorful colors or patterns, it is more upscale, optional 1-3 colors..

3. Steel to steel embossing device: embossing clear layer, paper smooth and smooth, high grade.

4.Correction device: to reduce the base paper in the feed process offset the range, improve the product pass rate.

The model porameters are only for reference

Machine Model | 5.0 or 5.2 FX-SP-S Automatic Production Line Of handkerchief machine |

Product Specification | 5.0 or 5.2 |

Raw material diameter | Ø1200mm (Ø>1200mm need order) |

Raw Material Requirements | 12-18g/mm ,width 180-210mm,2 to 4layers |

Control Method | PLC program control,setting by touch screen,inching paper |

Machine Speed | Maximum speed of 80 packets/min,normal production speed of 75 packets/min |

Main Unit Structure | Wallboard type,connected by bolts |

Machine Speed | Maximum speed of 800 pieces/min,normal production speed of 750 pieces/min |

Mode Of Driving | Synchronous belt gear and chain drive ,flat belt feeding |

Motors Power | 1.5kw |

Fan Power | 5.5KW |

Pressure Requirement | More than 0.4pa |

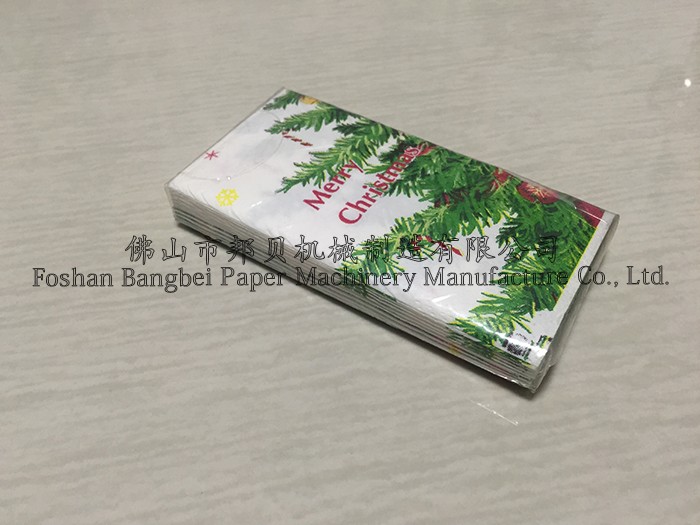

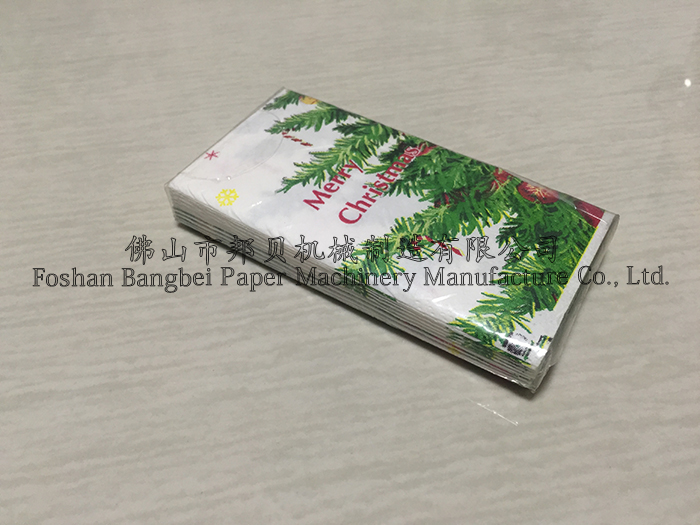

Tissue sample

Handkerchief paper

Handkerchief paper

Handkerchief paper

Handkerchief paper

Factory show

Factory appearance

R&D group

workshop

Debugging workshop

Debugging workshop

TUV Certificate

Industry certificate

The product is first issued by bobe paper machine,if you need to transmit it please give clear indication of where it is from.

We(BOBE-paper machine) are professional in making paper machine,such as Napkin Machine,Slitting Machine,Handkerchief Machine, Cartoning Machine,Sealing Machine ect.

Please feel free for any inquiry.

Contact us

Mr.Aries Mai

WeChat:

Mol:+86 18927245002

Mail:bobe_papermachine@126.com